Blog

Touch Screen LCD for Water Quality Analyzer

What is water quality analyzer?

Water is the source of life. Water quality analyzing is the premise to ensure safe water use. A typical water quality analyzer has two parts, sensors and main unit with LCD screen. Water quality analyzer can be used for many purposes:

? To identify whether water is meeting designated uses

? To identify pollutants and source of pollution

? To determine trends

Building water analyzer with Smart TFT LCD

This project uses Topway smart LCD module: HMT070ETD-1D

Resolution:1024x600

Interface:RJ45 RS232

Voltage:11V~26V

Temperature:-20°C ~ 70°C

Wide Viewing Angle :Yes

Size:7"

Touch Screen:CTP

NUCLEO-G070RB and hardware expansion board, PH, humidity & temperature sensors.

一、Project Goals:

1. Collect these data: water temperature and PH value, environment temperature and humidity

2. Collected values displayed on screen in real-time

3. Display historic data as graph

二、Project Steps

1. UI design

1) A picture as home page background, date time and collected data will be displayed here.

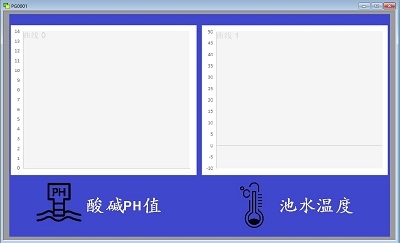

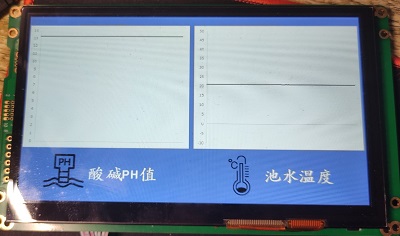

2) Historic data page for water quality

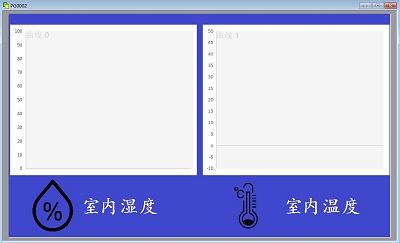

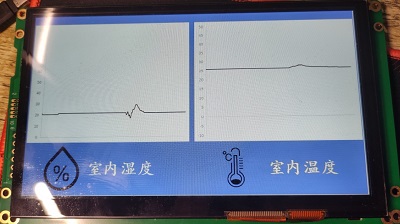

3) Historic data page for environment temperature and humidity

4) Create a project with TOPWAY SGTools

Import background pictures and icons into project

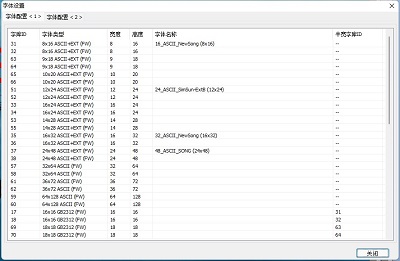

5) select a font type

You could modify font size, too.

6) Build all pages

These objects are used to build UI pages.

Static String: for labels on pages

Real Time Clock: display date and time

Number Element: display values collected from sensors

Graph Element: real-time plotting value on LCD in graph format

Touch Key: capture user touch action

7) Align icons

8) Variables and bindings.

Create 16-bit numeric variables to hold values collected from external sensors and RTC

Link page objects with newly created variables and modify the objects’ properties according to need.

9) Add three touch areas and set up their action targets

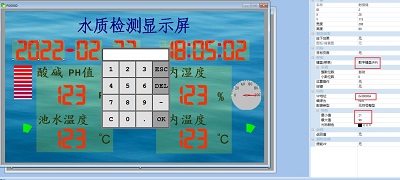

10) Use PIP keyboard acquire new date time values

2. Hardware design

3. Software design

1) LCD communication code

Send data to a selected variable

![]()

/**

brief LCD發送16位變量

param adr:變量地址

param dt:發送的變量

return 無

*/

voidlcd_send_pv16(uint32_tadr,uint16_tdt)

{

uint8_tsend_buf[32];

uint8_tidx = 0;

send_buf[idx++] = 0xaa;

send_buf[idx++] = 0x3d;

adr = ntohl(adr);//大小端轉換

memcpy((uint8_t*)&send_buf[idx], (uint8_t*)&adr, sizeof(uint32_t));

idx += sizeof(uint32_t);

dt = ntohs(dt);//大小端轉換

memcpy((uint8_t*)&send_buf[idx], (uint8_t*)&dt, 2);

idx += 2;

send_buf[idx++] = 0xcc;

send_buf[idx++] = 0x33;

send_buf[idx++] = 0xc3;

send_buf[idx++] = 0x3c;

send_data1(send_buf, idx);

}

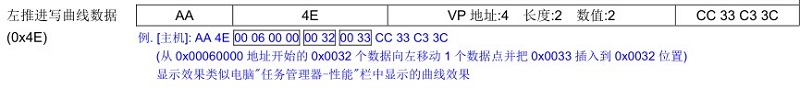

Send data for plotting graph

/**

brief LCD左推進寫曲線數據

param adr:變量地址

param adr_curve:插入位置

param dt:發送的變量

return 無

*/

voidlcd_send_curve(uint32_tadr,uint16_tadr_curve,uint16_tdt)

{

uint8_tsend_buf[64];

uint8_tidx = 0;

send_buf[idx++] = 0xaa;

send_buf[idx++] = 0x4e;

adr = ntohl(adr);

memcpy((uint8_t*)&send_buf[idx], (uint8_t*)&adr, sizeof(uint32_t));

idx += sizeof(uint32_t);

adr_curve = ntohs(adr_curve);

memcpy((uint8_t*)&send_buf[idx], (uint8_t*)&adr_curve, sizeof(uint16_t));

idx += sizeof(uint16_t);

dt = ntohs(dt);

memcpy((uint8_t*)&send_buf[idx], (uint8_t*)&dt, sizeof(uint16_t));

idx += sizeof(uint16_t);

send_buf[idx++] = 0xcc;

send_buf[idx++] = 0x33;

send_buf[idx++] = 0xc3;

send_buf[idx++] = 0x3c;

send_data1(send_buf, idx);

}

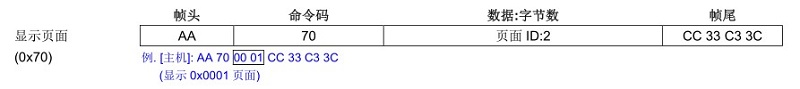

Show a page

/**

brief LCD跳轉頁面

param page:頁面地址

return 無

*/

voidlcd_send_page(uint16_tpage)

{

uint8_tsend_buf[64];

uint8_tidx = 0;

send_buf[idx++] = 0xaa;

send_buf[idx++] = 0x70;

page = ntohs(page);

memcpy((uint8_t*)&send_buf[idx], (uint8_t*)&page, sizeof(uint16_t));

idx += sizeof(uint16_t);

send_buf[idx++] = 0xcc;

send_buf[idx++] = 0x33;

send_buf[idx++] = 0xc3;

send_buf[idx++] = 0x3c;

send_data1(send_buf, idx);

}

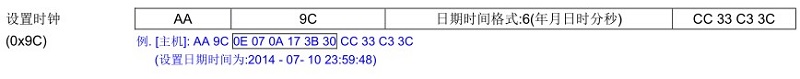

Set RTC time

/**

brief LCD設置時間

param page 無

return 無

*/

voidlcd_send_time(void)

{

uint8_tsend_buf[64];

uint8_tidx = 0;

send_buf[idx++] = 0xaa;

send_buf[idx++] = 0x9c;

memcpy((uint8_t*)&send_buf[idx], (uint8_t*)&my_rtc, sizeof(MYRTC));

idx += sizeof(MYRTC);

send_buf[idx++] = 0xcc;

send_buf[idx++] = 0x33;

send_buf[idx++] = 0xc3;

send_buf[idx++] = 0x3c;

send_data1(send_buf, idx);

}

Read RTC time

/**

brief LCD讀取時間

param page 無

return 無

*/

voidlcd_read_time(void)

{

uint8_tsend_buf[64];

uint8_tidx = 0;

send_buf[idx++] = 0xaa;

send_buf[idx++] = 0x9b;

send_buf[idx++] = 0xcc;

send_buf[idx++] = 0x33;

send_buf[idx++] = 0xc3;

send_buf[idx++] = 0x3c;

send_data1(send_buf, idx);

}

Code of receiving data

voidlcd_pro(void)

{

staticuint32_ttimer_lcd = 0;

if (timer6 - timer_lcd<9)

return;

timer_lcd = timer6;

if (lcd_rx.len<5)

return;

if (lcd_rx.rx_buff[0] != 0xaa)

{

memset((uint8_t*)&lcd_rx.rx_buff, 0, lcd_rx.len);

lcd_rx.len = 0;

return;

}

else

{

switch (lcd_rx.rx_buff[1])

{

case0x79://觸摸

lcd.page = lcd_rx.rx_buff[3];

lcd.touch_id = lcd_rx.rx_buff[4];

break;

case0x77://下發數據

if(lcd_rx.rx_buff[3] == 0x08)

{

if(lcd_rx.rx_buff[5] == 0x0A)//年

{

my_rtc.year = lcd_rx.rx_buff[7];

}

elseif(lcd_rx.rx_buff[5] == 0x0C)//月

{

my_rtc.month = lcd_rx.rx_buff[7];

}

elseif(lcd_rx.rx_buff[5] == 0x0E)//日

{

my_rtc.day = lcd_rx.rx_buff[7];

}

elseif(lcd_rx.rx_buff[5] == 0x10)//時

{

my_rtc.hour = lcd_rx.rx_buff[7];

}

elseif(lcd_rx.rx_buff[5] == 0x12)//分

{

my_rtc.min = lcd_rx.rx_buff[7];

}

elseif(lcd_rx.rx_buff[5] == 0x14)//秒

{

my_rtc.sec = lcd_rx.rx_buff[7];

}

lcd_send_time();

}

break;

case0x9B://讀取時間

memcpy((uint8_t*)&my_rtc, (uint8_t*)&lcd_rx.rx_buff[2], sizeof(MYRTC));

break;

default:

break;

}

memset((uint8_t*)&lcd_rx.rx_buff, 0, lcd_rx.len);

lcd_rx.len = 0;

}

}

2) PH value sampling

Sensors used in this project return analog signals

voidph_pro(void)

{

staticuint32_ttimer_ph = 0;

uint16_tadc_value = 0;

floatvol = 0.0;

if (timer6 - timer_ph>PH_COLLECT_TIME)

{

HAL_ADC_Start(&hadc1); //啟動ADC單次轉換

HAL_ADC_PollForConversion(&hadc1, 50); //等待ADC轉換完成

if(HAL_IS_BIT_SET(HAL_ADC_GetState(&hadc1), HAL_ADC_STATE_REG_EOC))

{

adc_value = HAL_ADC_GetValue(&hadc1); //讀取ADC轉換數據

vol = ((double)adc_value/4096)*3.3*2;//轉化為實際電壓值

printf("sensor log:adc_value = %d, vol = %.2fV.\n", adc_value, vol);

ph_buf[FILTER_N] = (uint16_t)((5.9647*vol+22.255)*10);//轉換為PH值

for (i = 0; i <FILTER_N; i++)

{

ph_buf[i] = ph_buf[i + 1]; // 所有數據左移,低位仍掉

}

pv.ph = MedianFilter(ph_buf, FILTER_N); //中值平均濾波

printf("sensor log:ph %d\r\n", pv.ph);

}

lcd_send_pv16(0x080000,pv.ph);//給LCD發送數據

lcd_send_curve(0x060000,224,pv.ph);//給LCD左推進發送曲線

timer_ph += PH_COLLECT_TIME;

}

}

3) Water temperature collection

With classic DS18B20

voidds18b20_pro(void)

{

uint16_ti = 0;

staticuint32_ttimer_ds18b20 = 0;

if (timer6 - timer_ds18b20>DS_COLLECT_TIME)

{

te_buf[FILTER_N] = DS18B20_Get_Temp();

for (i = 0; i<FILTER_N; i++)

{

te_buf[i] = te_buf[i + 1]; // 所有數據左移,低位仍掉

}

pv.te = MedianFilter(te_buf, FILTER_N); //中值平均濾波

lcd_send_pv16(0x080002, pv.te);//給LCD發送數據

lcd_send_curve(0x0600e0,224,pv.te+100);//給LCD左推進發送曲線

printf("sensor log:te %d\r\n", pv.te);

timer_ds18b20 += DS_COLLECT_TIME;

}

4) Environment temperature and humidity collection

AHT10 and IIC

voidaht_pro(void)

{

uint16_ti = 0;

staticuint32_ttimer_aht = 0;

if (timer6 - timer_aht>AHT_COLLECT_TIME)

{

AHT10ReadData(&tem_buf[FILTER_N], &hum_buf[FILTER_N]);

for (i = 0; i<FILTER_N; i++)

{

hum_buf[i] = hum_buf[i + 1]; // 所有數據左移,低位仍掉

tem_buf[i] = tem_buf[i + 1]; // 所有數據左移,低位仍掉

}

pv.tem = MedianFilter(tem_buf, FILTER_N); //中值平均濾波

pv.hum = MedianFilter(hum_buf, FILTER_N); //中值平均濾波

printf("sensor log:tem %d\r\n", pv.tem);

printf("sensor log:hum %d\r\n", pv.hum);

lcd_send_curve(0x0602a0,224,pv.tem+100);//給LCD左推進發送曲線

lcd_send_curve(0x0601c0,224,pv.hum);//給LCD左推進發送曲線

lcd_send_pv16(0x080004,pv.hum);//給LCD發送數據

lcd_send_pv16(0x080006,pv.tem);//給LCD發送數據

timer_aht += AHT_COLLECT_TIME;

}

}

5) Operation flowchart

4. Project at run-time

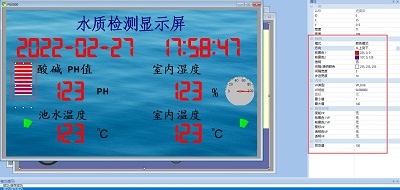

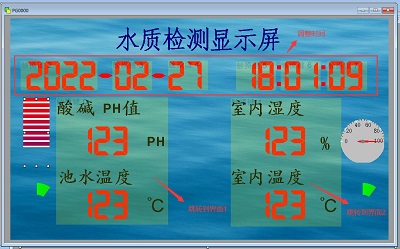

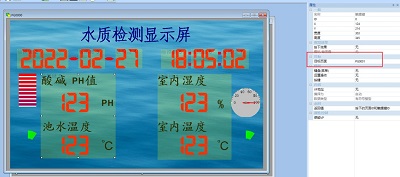

1) Home page

2) water quality historic data page

3) temperature and humidity historic data page

5. Summary

From above project, you can tell that creating user interface with Smart TFT LCD is very easy. Engineer doesn’t need to write any code to drive the LCD and respond to user input.